Upgrade Your Equipment with Reliable Bobcat Aftermarket Parts

Upgrade Your Equipment with Reliable Bobcat Aftermarket Parts

Blog Article

Unlocking Potential: Aftermarket Components as a Cost-Effective Service for Equipment and Heavy Tools

In the ever-evolving landscape of machinery and hefty tools maintenance, the utilization of aftermarket components has emerged as an engaging alternate worth exploring. While the idea may elevate brows among reactionaries, the advantages that aftermarket parts provide in terms of cost financial savings, high quality, and performance are not to be underestimated.

Expense Financial Savings and Value Suggestion

The cost financial savings and value proposition of using aftermarket parts for machinery and hefty tools are considerable factors that contribute to functional performance and financial stability in various markets. By deciding for aftermarket parts over initial equipment supplier (OEM) components, organizations can understand substantial price financial savings without jeopardizing on quality or efficiency. Aftermarket components are typically extra competitively valued than their OEM counterparts, enabling firms to lower repair and maintenance expenditures while still ensuring the appropriate performance of their equipment and tools.

Moreover, the value proposal of aftermarket parts prolongs past price financial savings. These parts are widely available and provide a wider option contrasted to OEM components, giving businesses with greater flexibility and convenience in sourcing the parts they require. Furthermore, aftermarket parts are understood for their top quality and dependability, meeting or perhaps going beyond industry standards in most cases. This reliability converts right into improved operational efficiency and reduced downtime, ultimately boosting total efficiency and productivity for companies that pick to take advantage of aftermarket options for their machinery and heavy tools demands.

High Quality and Compatibility Assurance

Stressing the vital significance of quality assurance and compatibility verification is essential when considering the utilization of aftermarket parts for machinery and hefty equipment. Guaranteeing that aftermarket components meet or go beyond industry criteria for quality is vital to maintaining the ideal efficiency and longevity of the equipment. Quality control procedures, such as strenuous testing procedures and qualifications, offer confidence to tools owners that the aftermarket parts will certainly operate reliably and efficiently.

Raised Schedule and Choices

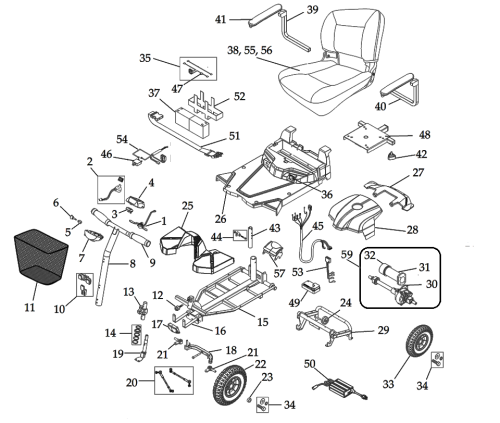

With an increasing market and growing demand, aftermarket components for machinery and heavy tools are currently providing increased accessibility and a wider variety of options to provide to the diverse needs of tools owners. This surge in schedule is driven by the aftermarket components industry's dedication to satisfying the specific needs of different machinery brand names and models. Equipment proprietors can currently access a vast array of aftermarket parts, varying from engine elements to hydraulic parts, electrical systems, undercarriage components, and more.

In addition, aftermarket components manufacturers are continually broadening their line of product to include components for a wider variety of machinery and hefty equipment, making certain that owners can find suitable substitutes despite the devices kind or model they have. This increased schedule and variety of aftermarket parts encourage devices owners to make cost-efficient decisions without endangering on quality or performance. Therefore, they can efficiently maintain, fix, and upgrade their machinery with self-confidence, knowing that aftermarket parts use a trustworthy choice to OEM elements.

Efficiency and Toughness Benefits

Enhancing machinery and heavy tools with aftermarket components brings notable performance and sturdiness advantages to tools owners. Aftermarket parts are typically have a peek here made with developments look what i found in innovation and products, offering boosted efficiency contrasted to original equipment producer (OEM) parts. Upgraded elements can lead to raised power, efficiency, and overall device abilities, causing enhanced efficiency and functional efficiency.

Additionally, aftermarket components are regularly crafted to be extra sturdy and durable than their OEM equivalents. This raised durability can translate to reduced downtime for repair and maintenance, inevitably conserving devices owners valuable time and money. By purchasing aftermarket components recognized for their toughness, machinery and heavy tools can hold up against rough operating problems and heavy workloads with better strength.

Fundamentally, the efficiency and toughness benefits of aftermarket parts contribute dramatically to maximizing the performance and longevity of equipment and heavy equipment. Tools proprietors stand to obtain a competitive edge by leveraging aftermarket remedies to boost the general performance and longevity of their possessions.

Sustainability and Ecological Effect

The application of aftermarket parts not just enhances the efficiency and resilience of equipment and hefty equipment however also plays a critical function in addressing sustainability worries and minimizing ecological impact. By going with aftermarket components, industries add to the decrease of waste generation since these parts are often sourced from recycled materials or with remanufacturing procedures. This practice find out this here aligns with the concepts of a round economic climate, where sources are made use of efficiently, and waste is lessened.

Additionally, aftermarket parts can extend the lifespan of equipment and tools, lowering the frequency of replacements and as a result lowering the overall carbon impact connected with producing new equipment. In addition, the production of aftermarket components usually entails less energy intake and less discharges compared to making initial tools maker (OEM) parts.

Conclusion

To conclude, aftermarket components provide a cost-effective remedy for machinery and hefty devices by offering price financial savings, quality control, enhanced availability, efficiency benefits, and sustainability advantages. These components not only offer a feasible alternative to initial equipment supplier parts yet additionally add to the total effectiveness and longevity of machinery and tools. Accepting aftermarket components can result in substantial price financial savings and improved efficiency, making them an important alternative for businesses seeking to maximize their resources.

By deciding for aftermarket components over original devices supplier (OEM) parts, services can realize significant cost financial savings without compromising on quality or efficiency (Bobcat Aftermarket Parts). Devices owners can currently access a broad variety of aftermarket components, ranging from engine parts to hydraulic components, electrical systems, undercarriage parts, and much more

Furthermore, aftermarket components manufacturers are continuously increasing their product lines to include parts for a more comprehensive array of machinery and heavy devices, making certain that owners can discover ideal replacements regardless of the equipment type or design they have. Aftermarket components are often developed with innovations in technology and materials, offering improved performance compared to original devices maker (OEM) components. Furthermore, the manufacturing of aftermarket parts often involves less power intake and less exhausts contrasted to making initial equipment manufacturer (OEM) parts.

Report this page